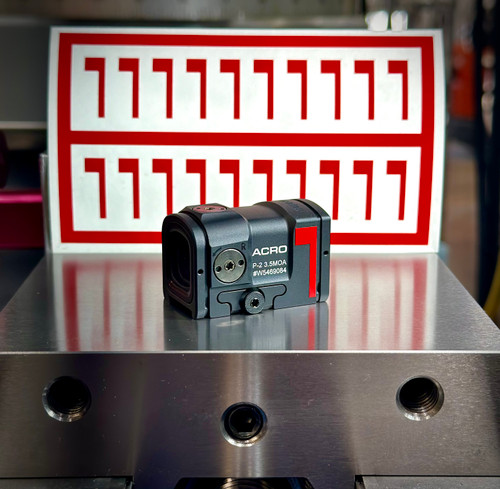

Our optics cuts are precision CNC milled to exacting tolerances to give you industry leading performance. A primary feature of our cradle cutting method is the fact the optic will be tight in the cut and will have extremely little to no ability to move once in place (this is by design). Our cuts will also have precise and consistent recoil bossing (where available) to add strength to the cut. This is to ensure the repeated reciprocal forces from firing are not translated exclusively to the mounting screws. No matter if you are in military/law enforcement community, competition community, or personal defense community, our cuts will ensure your optic survives the harshest of firing schedules.

*Optics Not Included*

*We highly recommend coating your slide to prevent rust and corrosion due to bare metal being exposed. If you select "no" to any of the coating services you are acknowledging that you're aware of the potenal issues that arise from not getting it coated.*

4 Reviews Hide Reviews Show Reviews

-

M&P milling

I received my slide with the aimpoint acro yesterday. I'm very happy with the job and the quality of work. I'm looking forward to heading to the range to test out the red dot.

-

Outstanding

Great job! My first optics cut and I am impressed. Perfectly fit into the slide and the coating is done so well it appears to be factory. I will be using VMW again for the next slide milling I need done!

-

Sight Milling and Cerakote

The work done on my M&P 2.0 slide was Immaculate. Crisp clean edges on the mill work and the cerakot to burnt bronze was best I've seen. Only down fall was it took almost 2 weeks over expected time allotment. Their work though speaks for itself.

-

M&P45c with ACRO

My M&P45c looks sick with the ACRO mounted. Vulcan Machine Werks is legit. The staff is very informative not only on the process, but various optics. They were the only ones I could find to do a rail cut on the M&P45c platform.